Innovation Lab

Bespoke design to solve tough actuation problems

OTM’s core business is designing and manufacturing precision Intelligent Actuator Solutions – wherever extreme performance and reliability is required. These range UAV control surface actuation and missile fin control to weapon sight and aircraft seat actuation and everything beyond. We’ve banked up a wealth of expertise and experience while working to develop extremely high specification units within these specialist fields.

Innovation Lab

Designed for the toughest conditions

That base technology, already built to operate in extremely tough conditions as befits those industries, can equally be applied to meet the needs of projects in many other spheres.

Innovation Lab

Solving unique problems

Given the opportunity to use our experience and engineering excellence to solve a unique problem away from our core areas, we will rarely turn it down. Consequently, we have a large number of solutions under our belt where we have met some tough challenges head on, and succeeded where many others had already failed.

Innovation lab

Our extensive library of actuator design solutions

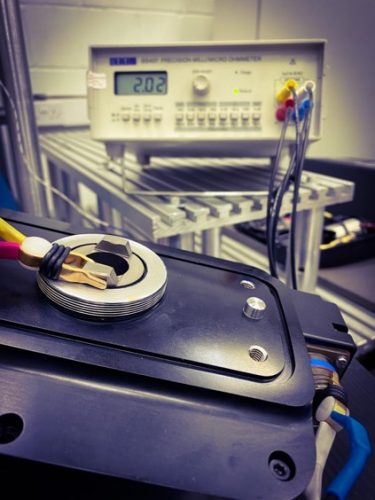

Over its almost 60 years, OTM has built up an extensive library of innovative actuator designs.

These could be single application specific or modifications to core solutions which may be applied to additional use-cases.

As a result, OTM is usually able to respond positive, in super quick time to even the most left field customer challenge.

Innovation lab

Partnering with world leading academia

In order to ensure that we continue to stay ahead of the precision actuator pack, OTM partner with some of the world’s leading academic institutions.

We are currently working with Brunel University, London’s Department of Electronic & Computer Engineering to improve advanced, integrated motor control electronics for use with its Intelligent Actuator Solutions.

Innovation Lab

8 step, solution-based innovation

The OTM design method is based around our proven 8-step process that has served us so well in delivering success in the past. This stringent method has helped us to approach and solve problems around actuator design in difficult situations – often where answers had seemed impossible to achieve.

The OTM Innovations Lab exists to tackle those problems that may sit slightly outside of our core industry specialties but are nonetheless appropriate to our expertise and technology. We are

happy to consider any problem our clients are prepared to throw at us so if you’re experiencing an ‘impossible’ challenge around actuator design and implementation do get in contact with us.

Our Solution-Based Innovation Process

Definition

Define the problem requiring a solution

Fact Find

Gather facts and make assumptions

End-state

Identify desired end-state

Success

Establish success measurement criteria

.

Options

Develop possible options / solutions

Analyse

Analyse and compare possible solutions

Select

Select and implement solution

Test

Test solution for effectiveness / impact

Some Innovation projects we have worked on........

Warrior Wiper Blade Actuator

Brushless DC motor with variable power capability enabling actuator to take on to maintain consistent power in poor conditions when there is accumulation of snow, mud or ice on the blades.

Aircraft Step Actuator

A bespoke hybrid actuator used in the deployment of the passenger access stairway on private jet aircraft.

Refuelling Hose Deployment Actuator

Faster, safer and more efficient winding of aircraft refuelling hose in a high pressure and time-critical military environment.

First Class Airline Seat Actuator

Tailored actuator solutions to provide easy airline seat motion control in a high quality customer service environment.

Drilling Probe Actuator

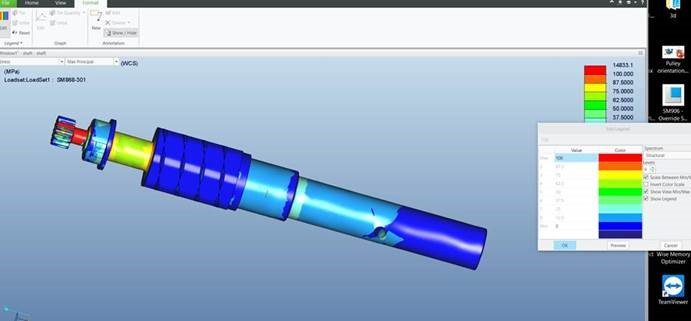

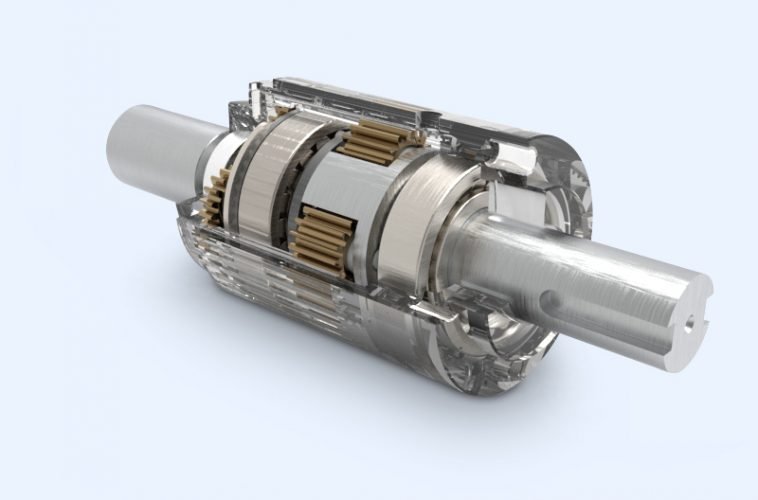

Epicyclic gearbox used in a steerable drilling probe. Fully functional when fully submersed in well slurry and designed to be user serviceable in the field.

Fast Jet Ejector Seat Control Actuator

In use by air forces worldwide to adjust ejector seat where human safety is a factor and available in both AC and DC versions.